Cornwall UK

- Welcome to Micro CoGen..

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

Pages1

#3

Lister, Petter, Blackstone diesel engines / Re: Lister startomatic - decompression control ?

September 05, 2011, 08:52:44 AM

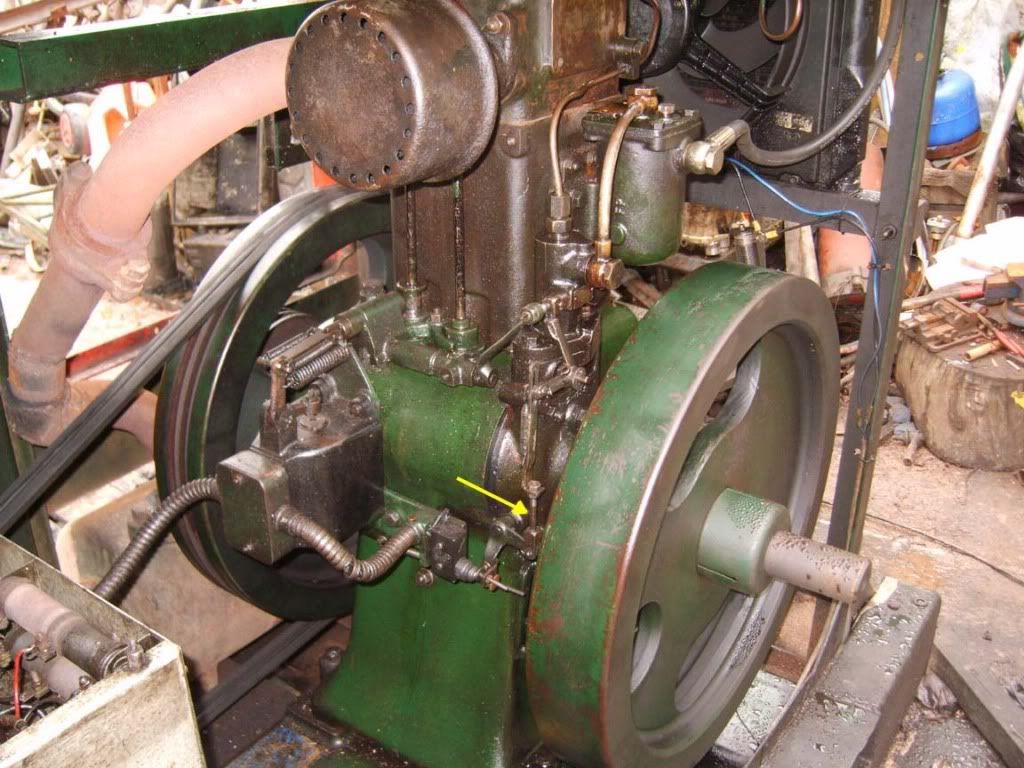

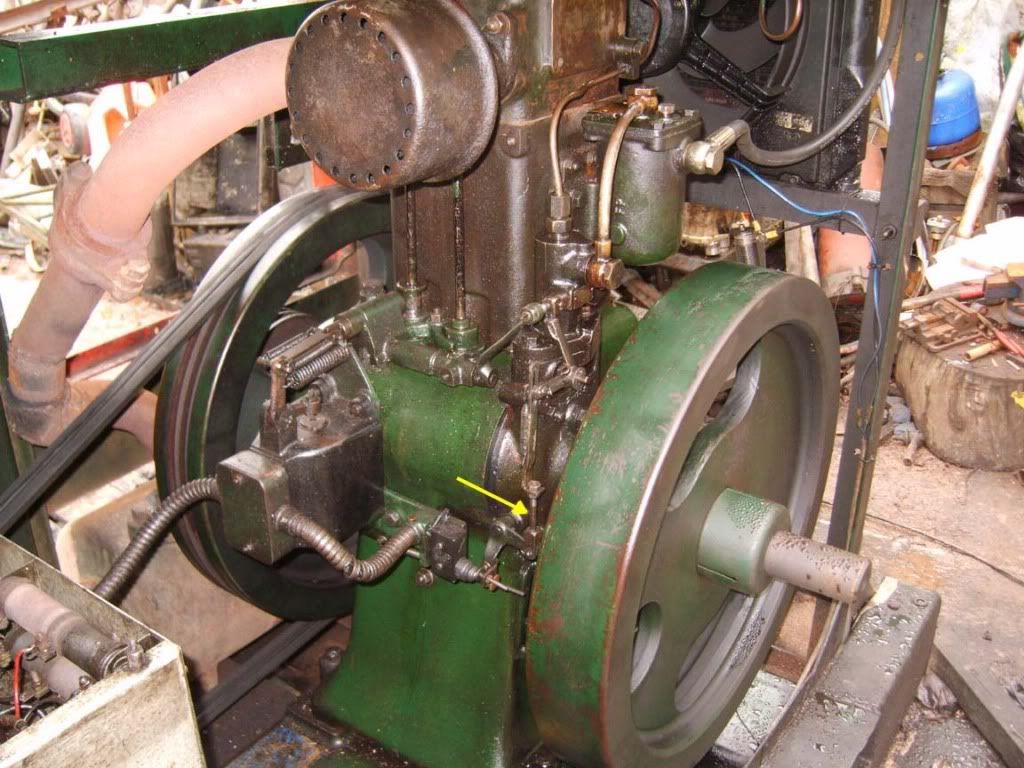

On the cs engined Start-O-Matics there are two types of decompression system.

The single cylinder types use a 24 volt DC solenoid and it is operated as soon as the engine starts spinning there is no delay apart from the fact that the solenoid has not got enough power to operate until the engine turns over and the exhaust valve lifts. There is no electrical delay. When the engine is up to speed the microswitch on the engine stops the starter motor and inserts a resistance in the wiring to the solenoid to reduce the power to the solenoid to stop it burning out.

On the twin cylinder cs engines (and SRs )the solenoid is AC operated (230 volts 50 hz or 110 volts 60 hz ) and is connected to the alternator AC output. When the engine is being spun over the alternator eventually produces enough AC voltage to energize the solenoid to put then engine onto compression. Thus giving the engine a good time to get up to speed before compression and then start.

One other point is the decompressor solenoid unit also operates the fuel on and off as well.

Mick

The single cylinder types use a 24 volt DC solenoid and it is operated as soon as the engine starts spinning there is no delay apart from the fact that the solenoid has not got enough power to operate until the engine turns over and the exhaust valve lifts. There is no electrical delay. When the engine is up to speed the microswitch on the engine stops the starter motor and inserts a resistance in the wiring to the solenoid to reduce the power to the solenoid to stop it burning out.

On the twin cylinder cs engines (and SRs )the solenoid is AC operated (230 volts 50 hz or 110 volts 60 hz ) and is connected to the alternator AC output. When the engine is being spun over the alternator eventually produces enough AC voltage to energize the solenoid to put then engine onto compression. Thus giving the engine a good time to get up to speed before compression and then start.

One other point is the decompressor solenoid unit also operates the fuel on and off as well.

Mick

#4

Listeroid/Petteroid/Clones / Re: Expected life expectancy from WMO?

January 23, 2011, 12:41:50 PM

Spencer

I did not realise that when you were talking about thinning WMO with RUG that the RUG you use is free. I made the assumption that you were paying for the RUG and hence my statement about putting twice the amount of kerosene in compared to RUG only makes sense if you are paying for the thinning agent. And live in the UK where kerosene is virtually tax free and half the price of RUG.

Thank you for doing the research on WMO I have been offered it for free but thanks to your advise I wont be going anywhere near it now. Unless the cracking can be sorted out.

Mick

I did not realise that when you were talking about thinning WMO with RUG that the RUG you use is free. I made the assumption that you were paying for the RUG and hence my statement about putting twice the amount of kerosene in compared to RUG only makes sense if you are paying for the thinning agent. And live in the UK where kerosene is virtually tax free and half the price of RUG.

Thank you for doing the research on WMO I have been offered it for free but thanks to your advise I wont be going anywhere near it now. Unless the cracking can be sorted out.

Mick

#5

Listeroid/Petteroid/Clones / Re: Expected life expectancy from WMO?

January 21, 2011, 05:16:52 PM

Kerosene (central heating oil) is about half the price of RUG so you can put twice as much in for your money which gives you more fuel.

Kerosene is a lot thinner than regular diesel and almost tax free.

Kerosene was a recommended fuel by Listers in the 1930s and I quote "Burning or Illuminating or Paraffin oil (Kerosene) may be used as a fuel but only if an admixture of 1/2 a pint of lubricating oil per 2 gallons of Paraffin is made."

The reason veg oil users use RUG instead of kerosene is because most people use it in cars and it is illegal to use kerosene in road vehicles because no tax has been paid on it. This does not matter for us because we use it for generating electricity and heating purposes.

Spencer who has lots of experience suggests 10 to 15 percent RUG in his mixture so using his method

100 litres WMO + 15 litres RUG = 115 litres = £19.20 at todays price of £1.28 per litre.

100 litres WMO + 30 litres Kero = 130 litres = £18.84 at todays price of £0.628 per litre

Mick

Kerosene is a lot thinner than regular diesel and almost tax free.

Kerosene was a recommended fuel by Listers in the 1930s and I quote "Burning or Illuminating or Paraffin oil (Kerosene) may be used as a fuel but only if an admixture of 1/2 a pint of lubricating oil per 2 gallons of Paraffin is made."

The reason veg oil users use RUG instead of kerosene is because most people use it in cars and it is illegal to use kerosene in road vehicles because no tax has been paid on it. This does not matter for us because we use it for generating electricity and heating purposes.

Spencer who has lots of experience suggests 10 to 15 percent RUG in his mixture so using his method

100 litres WMO + 15 litres RUG = 115 litres = £19.20 at todays price of £1.28 per litre.

100 litres WMO + 30 litres Kero = 130 litres = £18.84 at todays price of £0.628 per litre

Mick

#6

Listeroid/Petteroid/Clones / Re: Head gasket advise

January 18, 2011, 10:03:35 AM

Jens

I have used a gaskets to go 8/1 head gasket and it worked very well no weeping anywhere. I used it on a genuine Lister with no liner protrusion with an indian head. The crank broke on that engine and Ive taken the head off and measured the head gasket thickness and its 1.45mm thick when compressed. Ive just measured an old used genuine copper composite gasket and its 1 mm thick when compressed.

The method I used to set the piston to head clearance on the next engine I built was to bolt down the cylinder with spacers (3/4 drive sockets) and place a straight edge across the top of the block and measure the gap underneath the straight edge with a set of feeler gauges. Piston to head clearence on a 8/1 engine is 1.9mm to 2.03mm. So a gap of 0.45mm to 0.58mm would be required. I fitted excess base gaskets of a known thickness and just lifted the cylinder and removed the right amount to get the bump cleatrance correct.

Mick

I have used a gaskets to go 8/1 head gasket and it worked very well no weeping anywhere. I used it on a genuine Lister with no liner protrusion with an indian head. The crank broke on that engine and Ive taken the head off and measured the head gasket thickness and its 1.45mm thick when compressed. Ive just measured an old used genuine copper composite gasket and its 1 mm thick when compressed.

The method I used to set the piston to head clearance on the next engine I built was to bolt down the cylinder with spacers (3/4 drive sockets) and place a straight edge across the top of the block and measure the gap underneath the straight edge with a set of feeler gauges. Piston to head clearence on a 8/1 engine is 1.9mm to 2.03mm. So a gap of 0.45mm to 0.58mm would be required. I fitted excess base gaskets of a known thickness and just lifted the cylinder and removed the right amount to get the bump cleatrance correct.

Mick

#7

Listeroid/Petteroid/Clones / Re: Gib Key Dimensions

May 09, 2010, 02:50:14 PM

I have had a few genuine old lister engines with a shim inserted under the gib key. The main thing to watch out for when fitting gib keys is to make sure that they are not fitted to close to the flywheel. No closer than 1/2 inch for the tang or you wont be able to get the key out again. A shim under the key will be fine that what lister engineers used to do.

Mick

Mick

#8

Changfa/Redstone/Chinese diesels / Re: In search of a glow-plug for my S1100

March 27, 2010, 09:29:48 AM

Mark

You could have it helicoiled to 12mm x 1.25 and use one of the many available standard glowplugs.

Mick

You could have it helicoiled to 12mm x 1.25 and use one of the many available standard glowplugs.

Mick

#9

Listeroid/Petteroid/Clones / Re: Fuel solenoids causing troubles

February 07, 2010, 05:04:52 PM

You do not switch off a lister by switching off the fuel.

The only reason to switch off the fuel is to change the fuel filter or work on the fuel system.

The IP carries on pumping when you switch off the fuel and sucks air into the IP.

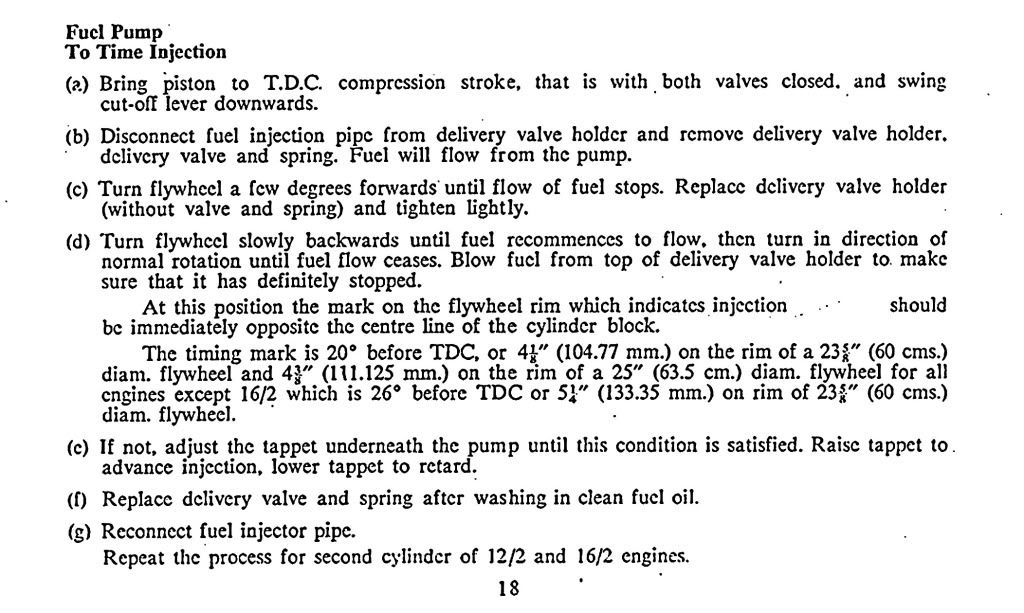

Heres a page from a genuine 1971 Lister cs manual that tells you how to switch off the engine.

Mick

The only reason to switch off the fuel is to change the fuel filter or work on the fuel system.

The IP carries on pumping when you switch off the fuel and sucks air into the IP.

Heres a page from a genuine 1971 Lister cs manual that tells you how to switch off the engine.

Mick

#10

Listeroid/Petteroid/Clones / Re: Drilled valve guides?

November 22, 2009, 06:53:18 PM

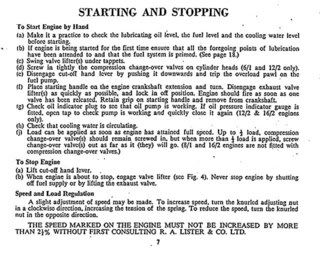

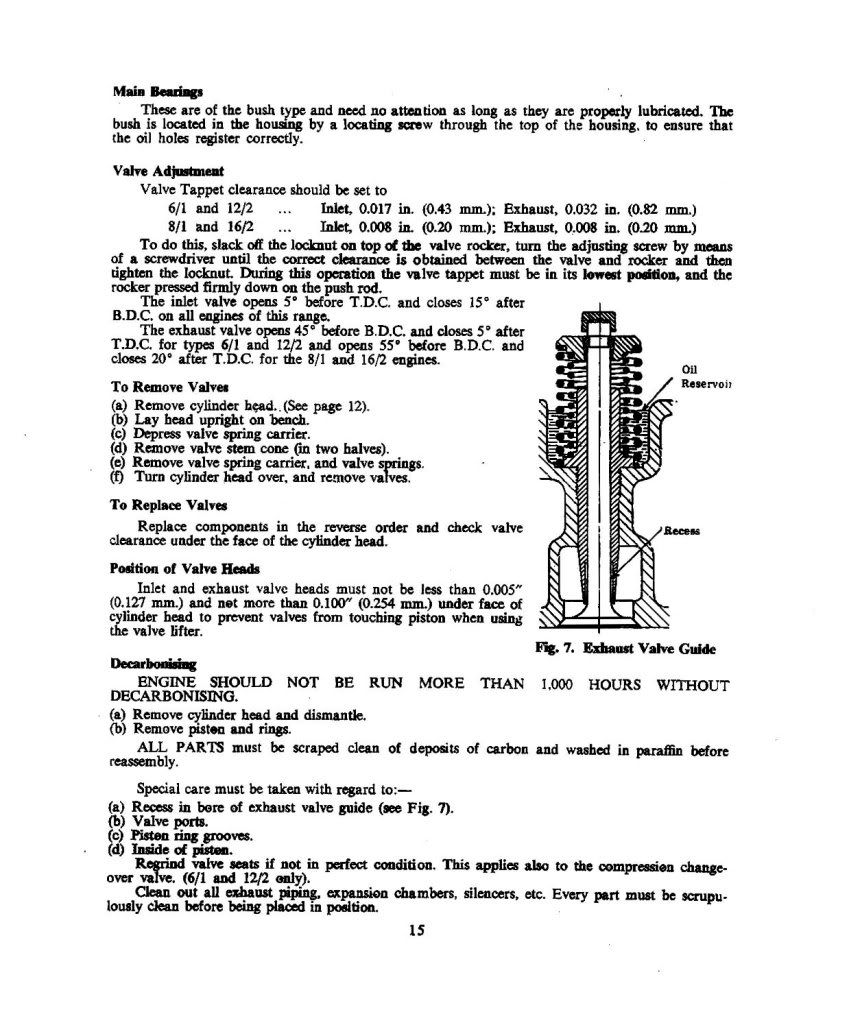

Genuine lister CS engines do not have holes in the valve guides. The oil should be just below the valve guide, as in picture below.

Mick

Mick

#11

Listeroid/Petteroid/Clones / Re: Excessive RPM drop under load ?

November 18, 2009, 10:47:10 AM

WJ

I have checked the lister manuals and the lister 3/1 and 6/1 have the same governor weights according to the part numbers.

The 8/1 weights are a bit lighter. Heres some pics.

Mick

8/1

6/1

I have checked the lister manuals and the lister 3/1 and 6/1 have the same governor weights according to the part numbers.

The 8/1 weights are a bit lighter. Heres some pics.

Mick

8/1

6/1

#12

Listeroid/Petteroid/Clones / Re: Cylinder Head Torque settings

November 17, 2009, 12:16:07 PM

It is not possible to correctly torque down a seven stud Lister CS head because the rocker gear gets in the way of 2 of the big head bolts. You need to leave the rocker assembly off to get to these 2 bolts.

The method I now use on my genuine 7 stud Lister CS is to leave the rocker assembly off and do a 3 stage torque method.

1 Torque to 45lbft the 4 main nuts and the 2 remaining smaller ones.

2 Torque to 65lbft the 4 main nuts and the 2 remaining smaller ones.

3 Torque to 100lbftl the 4 main nuts.

4 Fit rocker assembly and torque the last nut up to 65lbft.

5 Run the engine until nice and warm, then remove the rocker assembly and re torque the big nuts to 100lbft and the smaller nuts to 65lbft then fit the rocker assembly and torque the last bolt to 65lbft.

Most of this information came from Peter forbes site http://www.oldengine.org/members/diesel/articles/rrchapt8.htm a very interesting bit of information.

Mick

The method I now use on my genuine 7 stud Lister CS is to leave the rocker assembly off and do a 3 stage torque method.

1 Torque to 45lbft the 4 main nuts and the 2 remaining smaller ones.

2 Torque to 65lbft the 4 main nuts and the 2 remaining smaller ones.

3 Torque to 100lbftl the 4 main nuts.

4 Fit rocker assembly and torque the last nut up to 65lbft.

5 Run the engine until nice and warm, then remove the rocker assembly and re torque the big nuts to 100lbft and the smaller nuts to 65lbft then fit the rocker assembly and torque the last bolt to 65lbft.

Most of this information came from Peter forbes site http://www.oldengine.org/members/diesel/articles/rrchapt8.htm a very interesting bit of information.

Mick

#13

Listeroid/Petteroid/Clones / Re: Excessive RPM drop under load ?

November 15, 2009, 12:54:21 PM

It is possible to achieve quite good RPM regulation on a Lister 8/1 but it takes a bit of work to get it right.

To get the RPM correct you need a revcounter or a HZ meter and a load to put on the generator. I use two 1.5kw electric electric fires and a 1.5kw hot air gun on my 4.5kw Startomatic.

First of all start your set on low load then check what revs your engine is running at 850 for an 8/1 or 650 for the 6/1 or you can use a HZ meter and use 50HZ or 60HZ to set the revs correct. Then put maximum load on the generator and check the revs again it will probably drop. If the revs drop stop the engine and slightly lengthen or shorten the adjustable rod from the governor arm to the pump quadrant. Start the engine again check and adjust low load rev (50HZ or 60HZ) and then fully load up the generator again. It should have made an improvement to the revs. Keep on adjusting and reseting the rod and governor spring and it should be possible to get good revs regulation from min to max load. This takes quite a bit of time but it starts to make sense when you do it. Once you start adjusting the rod it gets better or worse and then you know which way to adjust it.

Mick

To get the RPM correct you need a revcounter or a HZ meter and a load to put on the generator. I use two 1.5kw electric electric fires and a 1.5kw hot air gun on my 4.5kw Startomatic.

First of all start your set on low load then check what revs your engine is running at 850 for an 8/1 or 650 for the 6/1 or you can use a HZ meter and use 50HZ or 60HZ to set the revs correct. Then put maximum load on the generator and check the revs again it will probably drop. If the revs drop stop the engine and slightly lengthen or shorten the adjustable rod from the governor arm to the pump quadrant. Start the engine again check and adjust low load rev (50HZ or 60HZ) and then fully load up the generator again. It should have made an improvement to the revs. Keep on adjusting and reseting the rod and governor spring and it should be possible to get good revs regulation from min to max load. This takes quite a bit of time but it starts to make sense when you do it. Once you start adjusting the rod it gets better or worse and then you know which way to adjust it.

Mick

#14

Listeroid/Petteroid/Clones / Re: 4 flywheels?

November 05, 2009, 03:07:43 PM

This message is posted on lister power currently a 8/1 engined 4.5kw start o matic I have been running these for 8 years at first 8 hours a day and now I run from 12 noon to 12 midnight every day on WVO .

I have used both 6/1 engined startomatics and 8/1 engined startomatics over the last 8 years and the 6/1 has always flickered even though the 6/1 start o matic flywheels are much heavier being 25" diameter than the 8/1 start o matic flywheels at 23" diameter. They are the same casting but machined to a smaller diameter. Listers also fitted a very heavy pulley to the generator on both models about 3 times the mass of a standard pulley.

I have been reading posts for years about flicker on Lister (Listeroid) CS engines and it only seems to occur on the lower rpm engines. I think 650rpm is just to slow to run the engine and expect it to not slow down between power strokes. None of the 8/1 engined units that run at 850 rpm seem to flicker at all. Listers got it right with their 8/1 engined units.

Maybe a 6/1 with heavy flywheels, heavy generator pulley and AVR might cure flicker on a 6/1 engined generator.

Mick

I have used both 6/1 engined startomatics and 8/1 engined startomatics over the last 8 years and the 6/1 has always flickered even though the 6/1 start o matic flywheels are much heavier being 25" diameter than the 8/1 start o matic flywheels at 23" diameter. They are the same casting but machined to a smaller diameter. Listers also fitted a very heavy pulley to the generator on both models about 3 times the mass of a standard pulley.

I have been reading posts for years about flicker on Lister (Listeroid) CS engines and it only seems to occur on the lower rpm engines. I think 650rpm is just to slow to run the engine and expect it to not slow down between power strokes. None of the 8/1 engined units that run at 850 rpm seem to flicker at all. Listers got it right with their 8/1 engined units.

Maybe a 6/1 with heavy flywheels, heavy generator pulley and AVR might cure flicker on a 6/1 engined generator.

Mick

Pages1